Introduction - fish are also animals

Fish in organic farms – organic norms and standards regarding fish farming

The IFOAM norms and standards also cover fish and aquatic farming, and defines aquaculture as ‘The managed production of aquatic plants and/or animals in fresh, brackish or sal water in a circumscribed (demarcated) environment. Organic aquaculture follows the same general rules as all other organic animals regarding feeding, breeding and human management. In addition, the following requirements should be met, when establishing or converting to organic aquaculture:

6.1.2 The conversion period of the production unit shall be at least one life cycle of the organism or one year, whichever is shorter.

6.1.3 Operators shall ensure that conversion to organic aquaculture addresses environmental factors, and past use of the site with respect to waste, sediments and water quality.

6.1.4 Production units must be located at an appropriate minimum distance from contamination sources and conventional aquaculture.

In aquatic ecosystems, the biodiversity of natural aquatic ecosystems should be considered, as well as the health of the aquatic environment, and the quality of surrounding aquatic and terrestrial ecosystems, This means that all relevant organic requirements regarding ecosystem management shall be met, and e.g. introduced and cultivated species should not escape out to the surrounding environment. Waste and nutrients should also not be let into the natural environment, and clearly all artificial fertilizers and pesticides are prohibited.

With regard to breeding of organic fish, their life should start in an organic unit. It can be permitted to buy in non-organic fish to an organic farming system, given that they will spend at least two thirds of their lives there, and die to the norms, artificially polyploided organisms or artificially produced monosex stock shall not be used. Only breeds and breeding techniques suited to the region should be used.

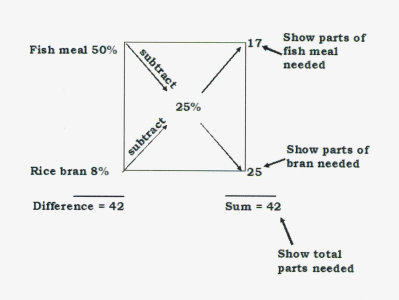

The general principle of feeding is that ‘Organic aquatic animals receive their nutritional needs from good quality, organic sources’, that is, they shall be fed organic feed. Until 31st Dec. 2014, a limited amount of non-organic feed can be used if there is no organic feed available, and in areas where organic aquaculture is not well established yet.

Use of water containing human excrement is prohibited, as it can mean transfer of certain diseases.

Feeding fish is a challenge, because some of them would live from fish and smaller animals in nature, and therefore they should be fed with these animals, although they can grow and seem fine on being fed with plant products.

Aquatic animal health and welfare

The general principle for animal health and welfare for aquatic animals is very much similar to that of other animals: ‘Organic management practices promote and maintain the health and well-being of animals through balanced organic nutrition, stress-free living conditions appropriate to the species and breed selection for resistance to diseases, parasites and infections.

The same rules for use of veterinary medicine applies for fish, such as medicine for prevention is prohibited, and the first choice should be natural methods and medicines. Use of chemical allopathic veterinary drugs and antibiotics is prohibited for invertebrates (other aquatic animals than fish, e.g. shrimps). Synthetic hormones and growth promoters are prohibited for use to artificially stimulate growth and reproduction. Stocking density must not compromise animal welfare; this should be adjusted to age and breed of fish. Apart from this, it is said (Norms 6.6.6): ‘Operators shall routinely monitor water quality, stocking densities, health, and behavior of each cohort (school) and manage the operation to maintain water quality, health, and natural behavior’.

When organic aquatic animals are transported and slaughtered, they should be subjected to minimum stress, and their species specific needs shall be respected, like with all other animals. The operator shall handle live organisms in ways which are compatible with their physiological requirements. Requirement 6.7.3 furthermore states:

Operators shall implement defined measures to ensure that organic aquatic animals are provided with conditions during transportation and slaughter that meet animal specific needs and minimize the adverse effects of (a) diminishing water quality, (b) time spent in transport; (c) stocking density, (d) toxic substances; (e) escape.

Aquatic vertebrates (fish) shall be stunned before killing, and it should be ensured that the equipment for this is sufficient to remove sensate ability and/or kill it.

Aquaculture

Aquaculture refers to the farming (propagation and rearing) of aquatic (water dwelling) organisms that include fin fish, mollusks, crustaceans and aquatic plants in controlled or semi controlled environments. The farming activities involve interventions such as stocking, feeding and protection from diseases and predators to enhance productivity.

However Aquaculture is used interchangeably with other terms like fish farming, pisiculture, pond fisheries and pond culture.

Mariculture refers to aquaculture done in marine (ocean) environments.

Some examples of aquaculture include:

- Algaculture: Production of seaweeds and other algae

- Fish farming: Farming of Fin fishes (e.g. Tilapia), shrimps, shellfish, cultured pearls etc.

Aquaculture in Kenya

© Mbugua Mwangi

|

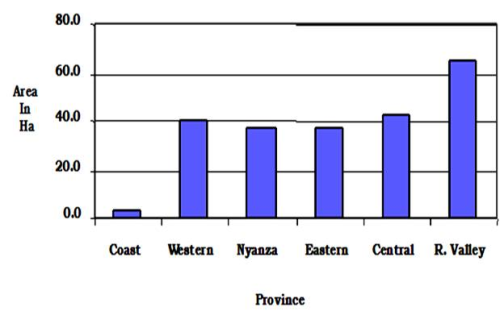

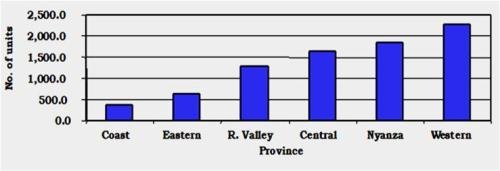

| Number of production units by province |

|

© Mbugua Mwangi

|

|

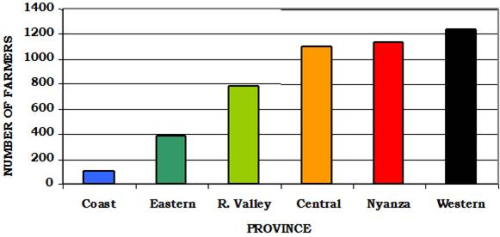

| Number of farmers by province |

| © Mbugua Mwangi |

|

There are two broad aquaculture divisions in Kenya:

- Marine aquaculture

- Fresh water culture

With an Indian Ocean coastline of about 600 km, mariculture is yet to realise any sensible development and therefore fresh water culture dominates aquaculture activities.

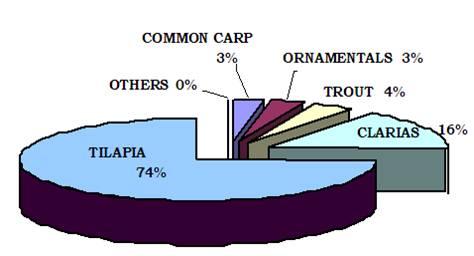

Fresh water aquaculture can be divided into:

- Cold water culture involving culture of Rainbow trout (Oncorhynchus mykiss) in highland areas

- Warm water culture involving the culture of Tilapine fishes, the African catfish, common carp and a variety of ornamental fishes in low land regions of the country

The total area under aquaculture in Kenya stands at 722.4 ha which include culture-based fisheries. National average productivity stands at about 5.84 Mt/ha/year while the total production from this utilized area average 420,000 kg per year.

The Fish Farming Enterprise Productivity Program (FFEPP), started in mid 2009 and aimed at increasing production of farmed fish from 4000 MT to over 20,000 MT in the medium term and over 100,000 MT in the long term. In the first year of the program, over 27000 fish ponds were dug; 200 ponds in each of 140 constituencies countrywide. This alone created a national short-term demand of about 28 million certified tilapia and catfish fingerlings and over 14,000 metric tonnes of formulated fish feeds. The multiplier effect resulting from farmers digging their own ponds is expected to increase the demand for fingerlings to over 100 million and the demand for fish feeds to 100,000 MT in the medium term (Charo-Karisa and Gichuri, 2010).

Considerations before investing in organic aquaculture

Thorough planning is therefore a must before any investment is made. Planning involves a detailed evaluation of the biological, economic, and socio-legal feasibility of production. Remember that economic considerations are as important as biological considerations in aquaculture. Socio-legal issues are potentially capable of limiting or even making it completely impossible to undertake aquaculture production.

It is essential to ascertain that the business concept is sound. Ask whether:

- There are adequate and profitable markets for proposed product(s): you can sell all the fish you are going to produce at a good price

- You have a suitable site for the proposed production: you have a good place were the pond can be established.

- You have enough resources to meet the projected targets: you have enough money or can get loans to pay all the investments and the startup costs.

- Your financial projections are realistic, robust and consistent: you can survive a period with low prices or low yields as expected.

- You have the expertise to produce: you know how to produce fish in an animal friendly way or know somebody who can help you with it.

- You can get adequate essential support services: you are sure that people you relay on, will be able to help you

- Your proposed undertaking is in accordance with organic principles, meets all the organic regulations, meets environmental, social and legal requirements: in your fishpond the fish has a good life, it does not pollute the surroundings, does not cause trouble with the neighbors and meets all community and country laws and regulations.

These questions should be answered in a well thought out BUSINESS PLAN and will provide you with a written document to serve as an overall plan for your operations.

Business planning is important to both new and established aquaculture enterprises. It enhances the chances for success and helps avoid costly mistakes. This plan will be helpful when looking for financiers, because many financial institutes require a formal business plan. A business plan should be a working document that is reviewed and updated at least on yearly basis. Importance of business planning:

- To convince possible financers that is safe to finance your business. Many potential and existing fish farmers have difficulty obtaining financing

- To make possible financers clear what you are going to do and that organic aquaculture is a good way of farming. Potential financiers may not be familiar with aquaculture as a viable investment

- Thinking and talking about possible problems, challenges and sollutions of the future enterprise prevents pitfalls afterwards. Proper planning for the business will help avoid mistakes

- Researching the possibilities for your organic products and possible customers to sell it to gives a clear view in the marketpossibilities. Proper planning for the business can also minimize risks associated with the market, production and financing

A business plan consists of:

- Description of the proposed production site (see pond construction)

- A Marketing plan/strategy: how much, to whom, at what price are you going to sell my organic fish. Description of production techniques/strategy: how are you going to produce, what equipment and installations are you going to use, is power (and it what form) needed, is transport available, is the young fish supply secured, will the water-quality be sufficient at all times, do you employ workers, are they skilled enough.

- Financial analysis of the proposed venture. How much money do the different financers supply and at what interest rate, for what period and how much should be paid back. Is there a penalty when you pay back earlier.

Where will I sell my fish? Surprisingly this question is asked very often by very many producers deep into their production cycle. Others ask this question after they have harvested their fish. Serious producers should ask and get answers to this question well before they go into production.

- What organic products does the market demand?

- What quantities does the market demand?

- What production resources do I have?

- Can the resources meet the proposed production?

- Which organic products am I capable of producing?

- What quantities can I realistically supply?

- When does the market want them supplied?

- What quality does the market require?

- Can I meet these standards?

- Is it possible to get a bulk buyer?

- How many buyers of organic fish are there in the region

- Does the demand in the market justify the intended production?

- What prices is the market ready to pay?

- Is it cost effective to produce at the offered prices?

- What competition exists in this field and how do I deal with it?

- Are the existing physical infrastructure (roads, power telecommunication etc) sufficient to meet the marketing needs for the produce?

After answering these, the entrepreneur should be able to make a decision on whether to continue or abandon the proposed production. If the entrepreneur decides to go on, then, it is time to develop a marketing strategy.

A marketing strategy is a plan to achieve the financial goals of the entrepreneur. The strategy should address; the products, product prices, advertisement and where to sell as regards marketing. Ideally, the products must be sold for more than the production cost and quantities that allow the producer to make gains and remain in business.

Marketing strategy involves:

i. Analyzing the market situation

ii. Formulating marketing goals

iii. Evaluating and selecting suitable marketing alternatives

i. Analyzing market situation

To do this, the entrepreneur should have a good knowledge of:

- Potential customer

- Modes of marketing (e.g. do you need to draw agreements, do you have to go through brokers etc)

- Product prices and their seasonality

- Product forms acceptable by the market

- Product quality requirements including regulation governing this

- Consumer preferences

- Quantity requirements

- Modes of payments and frequency

- All costs involved

- All competing products

- Alternative markets

- History regarding prices, demand, supply, product spoilage, product rejection etc

ii. Marketing goals

The goals must be realistic and achievable; otherwise the producer will be groping in darkness without purpose. In formulating marketing goals, the producer must ask, and be able to answer, the following:

- What is the targeted production?

- Is this achievable?

- What is the size of the target market in terms of geographical extent and consumer number?

- Is it possible to reach this market?

iii. Marketing alternatives

- Hotels, restaurants, retail markets and fish (sea food) shops including supermarkets: This could be out of reach of most small scale producers because they might not meet the frequency and quantity requirement of such outlets. However they can easily overcome this by forming marketing groups.

- Farm Gate Sales: Where local demand for fish is high, this offers a very good option. It removes the problems associated with taking the produce to distant markets. However it necessitates for proper storage facilities like deep freezers or cold rooms and some degree of processing and packaging.

- Sales to whole sellers, fish processors and large institutions: The advantage here is that large quantities can be disposed off at once and terms of supply and payment are normally stipulated in a legal contract. But this is only suitable for large scale producers or for farmers selling together (in a cooperative or other form of joint selling).

When planning for commercial aquaculture, the following aspects of production must be considered very critically:

i. Species to be produced

ii. Production site

iii. Production technology

I. Species to be produced

The choice of what to produce will be guided by:

a) Market preference

b) Ecological requirements of the species

c) Production technology of the species

d) Resources available to produce

The species to be produced must not only be marketable but also suited for the climate and be produced cost effectively. Different species require different climatic conditions to perform optimally. For example:

- Nile tilapia and African catfish require warm water of more than 25°C to achieve high growth potential. Growth of these fish is quite slow at elevations greater than 1600 meters because the water temperatures are very low. For best performance, average water temperatures of about 28°C are best. In Kenya, such regions are to be found in low land areas. In areas where temperatures are lower, a larger pond surface area can compensate for that. High sunlight intensity is also preferred for tilapia culture under semi-intensive production.

- Trout require cold, fast flowing clean water of less than 18°C for growing out and below 10°C for hatchery production. Such conditions in Kenya are to be found in high altitudes areas.

It is also important to know whether the species selected for production is adaptable to intended culture conditions and there is adequate knowledge of the reproductive biology, nutritional requirements, common diseases and parasites of the species. Also important is to ascertain that the species proposed for production is being profitably produced at commercial levels by other producers.

Other issues to consider, which are equally important are:

- Is there a reliable supply of good quality juveniles at a reasonable price, for stocking?

- Are you capable of establishing your own seeds (juveniles or ova) production capacity?

- Is there quality feed for the species and are the prices cost effective?

- Do you have a reliable and affordable source for specialized production supplies and equipment?

A good species should have the following characteristics:

- Adaptable to culture conditions

- Fast growth rate, from egg to market size

- Simple and inexpensive dietary requirements

- Hardiness and resistance to diseases and parasites

- Producer can have full control over the life cycle processes in captivity

- Easy market acceptability

- Availability of advanced and proven production technology

II. Production site

The proposed site should have the following characteristics:

- Be located in a region suitable and allowed for aquaculture production

- Have a climate suitable for the species intended for production (preferably indigenous to the area)

- Be well drained and protected from floods: when flooded the fish will escape/disappear.

- The topography and the soils should be suitable for the construction of the proposed production system

- Have adequate and preferably free flowing good quality water supply. This is the life line of aquaculture and is a must.

- Water is the key to a good site and not a matter of choice.

- Water should be available throughout the year

- Water must be free from pollution e.g. pesticides and other detrimental chemicals

- Accessible throughout the whole production cycle and have easy access to services and technical assistance

- Have adequate space for intended function and possible future expansion

- Located on site acceptable under local and environmental management legislation

- Have good Infrastructure like:

- Roads to bring supplies to the farm and take the products to the market? When export markets are targeted, air or water transport must be available.

- Air or water transport where export markets are the targeted

- Adeqiate (3-phase) power where intensive production systems are proposed

- Telephone service may be needed to run the enterprise efficiently

- Have good security

III. Production technology

The different species cultured have each their ecological requirements: feeding and breeding as well water quality. Aquaculture is done at different management and intensification levels. On small-holder farms it will mainly be in earthen ponds but even on a small scale the requirements and needs of the fish must be met and the production must add to the economics of the household. The choice of the production level will depend on:

- The species of choice

- Availability of the needed technology

- Potential prices of fish

- Available resources

- Available capital

- Availability of essential inputs for example feeds, power, skilled labour, professional expertise etc.

Depending on the proposed targets and the resources available, the producer will make a choice for an extensive or an intensive system:

In these systems little or no input is used in the production. Fish are stocked in cages, still water earthen ponds and other water impoundments (for example reservoirs) and let to fend for themselves. Low costs (recourses and labor), low stocking densities and thus low yields characterize the systems. The main cultured species are Tilapines (e.g. Oreochromis niloticus), Clarias gariepinus and Cyprinus carpio. These are low input-low out put production systems. Majority of the small scale, subsistence fish farmers in rural Kenya fall in this category. Production in these systems ranges between 500 and 1500 Kg/Ha/year. These systems can be organic because they don’t use chemical fertilizers and artificial feed. The fish can be sold on the local market.

|

| Fish culture cages |

|

© Mbugua Mwangi

|

|

| Small Scale Fish Farm. |

|

© Mbugua Mwangi

|

Semi-intensive systems

These systems form the bulk of aquaculture production in Kenya. In these systems still water earthen ponds and cages are used as holding units for fish culture. Still water pond culture uses the natural productivity of the water to sustain the species under culture. However to enhance productivity, the ponds are fertilized using both chemical and organic fertilizers at varying proportions to enhance productivity. Exogenous feeding using cereals bran and other locally available feeds is done to supplement pond productivity. Polyculture of Oreochromis niloticus, Clarias gariepinus and Cyprinus carpio is practiced with various combinations of species.

Commercial production in these systems ranges between 1 to 3 Kg/m2/year depending on the management levels individual farmers employ. There are Tilapia/Catfish producers in Western Kenya who have achieved productions between 6-10 Kgs/m2/year.

|

| A well fertilized pond in an ornamental fish farm in Kenya |

|

© Mbugua Mwangi

|

|

| Simple peletizing machine |

|

© Mbugua Mwangi

|

In these highly industrialized systems water flows in and out continuously (flow through). This allows higher stocking densities. The systems require good supply of good quality water. Less land is required to produce the same quantity of fish as compared to extensive and semi-intensive systems. The systems employ mainly raceways, various types of tanks and floating cages as holding units. In these systems, more fish are produced per unit area by complementing or substituting the productivity in the culture units by feeding from outside using complete feeds (the feeds are specifically manufactured for the species under culture) and water aeration. Such operations require high initial capital investment and high operational cost.

They are mainly suited for high value fish. There are very few such operations in Kenya and most of them produce Rainbow trout. Production in these systems range from 10 to 50 kg/m2/year. This depends on the management levels employed by individual producers. This production can go higher with better management and quality feeds.

|

| Simple floating cage |

|

© Mbugua Mwangi

|

|

| A paddle wheel aerator in action in an intensive fish farm i |

|

© Mbugua Mwangi

|

Economic analysis for proposed aquaculture venture (advanced)

Viability Analysis

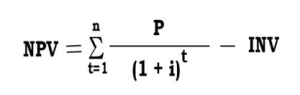

One way of evaluating whether an opportunity such as a new aquaculture investment is worthwhile in the long-term, or to choose between aquaculture opportunities which vary in size, is by use of capital budgeting. Popular methods of capital budgeting include net present value (NPV), and internal rate of return (IRR). Pay-back period (PBP) and the break even point (BEP) are also used as indicators of feasibility of investments.

Net Present Value (NPV) is used in the analysis of the profitability of an investment or project to give indication of the today's value of what will be earned in future. It is the futures net cash inflows discounted to today's value. If the NPV of a prospective project is positive, the project is profitable but if it is negative, the project should be abandoned because cash flows will also be negative. The higher the NPV value, the more profitable an investment is.

NPV is given as:

|

Where:

P = The net cash flow

i = The interest rate or the marginal cost of capital

t = Expected project life

INV = Initial investment

In addition to the formula, net present value can be calculated easily using tables, and much easier by use of computer soft wares like the Microsoft Excel spread sheet.

Internal Rate Of Return (IRR) indicates the estimated rate of return that a project is expected to generate to an investment. This can be viewed as the efficiency of an investment to turn profit.

IRR is the interest rate at which the NPV is zero. It equates the present value of the expected future cash flows or receipts to the initial investment. Equation used for IRR is that for NPV, it is solved for i, the interest rate at which NPV = 0.

IRR can be calculated easily by use of computer software like the Microsoft Excel spread sheet.

When evaluating possible investments options, it is important to remember that the NPV method is better that the IRR. The major limitation of IRR measurement is that it uses one single discount rate to evaluate every investment. However, discount rates do change significantly and therefore without modification, IRR evaluation will not be adequate for long-term projects for which discount rates are expected to vary.

Pay Back Period (PBP) is the time required to recover the cost of an investment through the net cash revenues it generates. It is calculated by dividing the initial investments cost by the accumulated profits before depreciation. However, this analysis does not take into consideration cash flow after the payback period. This method should only be used therefore as a first approach at the initial stages of evaluation to give an indication of the payback period and may not be relied upon to rank investments on basis of viability. PBP is given as:

PBP=I/E

where:

PBP = payback period in years

I = initial investment

E = Accumulated profits before depreciation

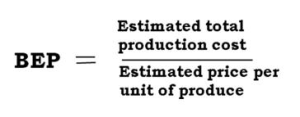

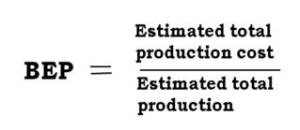

Break even Point (BEP) describes how much a project must produce to cover for the total cost of production. At the BEP, the revenue generated by a project equals the total cost incurred. An investor will need to know this to weigh this against production possibilities available. However, this method like the PBP should only be used as a first approach before proper evaluation is conducted because it does not show profitability of projects.

BEP considers the Economics of Scale which means the quantity of fish needed to be produced and sold at the current market price to pay all cost of the operation and make enough profit for the owner. In general the smaller the system, the more it costs to build and operate per quantity produced. This is because certain fixed costs remain the same no matter how much fish are produced.

For aquaculture investment, BEP can be derived for production quantities and produce prices. BEP analysis for production quantities is derived by calculating how much an enterprise should produce per hectare, considering the estimated market prices for the products, to be able to cover for the total production cost. The BEP for the produce prices is calculated by deriving the price at which the produce must be sold to cover the total cost of production.

| BEP for production quantity is given as: |

|

| BEP for produce price is given as: |

|

Financial ratios are used to give an indication of not only how likely a project will turn a profit, but also how that profit relates to other important investment characteristics of the project. High revenues alone do not necessarily translate into profits for the investor. A project must have the ability to clear all of its expenses and costs. These ratios are used to assess a business's ability to generate earnings as compared to costs incurred during a specific operation. They provide a comparison of profits generated and what have been invested in a project. For most of these ratios, having a higher value is an indication that the investment is good. Such ratios will include return on investment, return on equity, return on asset and operating profit margin ratio.

i). Return On Equity (ROE) indicates how much profit an investment generates with the equity.

ii). Return On Assets (ROA) is an indicator of how profitable an investment is relative to its total assets.

iii). Operating Profit Margin Ratio (OPMR) gives an indication of how much of the gross income is actually profit.

iv). Return On Investment (ROI) gives an indication of how an investment returns relate to the total invested capital.

These ratios are derived as:

i). ROE: Net income from operations divided by total equity

ii). ROA: Net income from operations divided by total

iii). OPMR: Operational gains plus interest divided by Gross income

iv). ROI: Net income from operation divided by Debts plus capital

Sensitivity of an investment to aspects of production is very important. Some of these aspects can be very volatile and their changes might have enormous effects on the profitability of projects. For investors to be able to make choices on where and how to invest, they need to know how likely variations on production output, cost of inputs or even changes in the market prices for the products will affect their future cash flows and net incomes.

To be able to carry out a proper sensitivity analysis, an entrepreneur needs the following information for each of the investment type:

Capital investment costs estimates:

- a) Cost of land

- b) Cost of construction of buildings and fish production facilities

- c) Cost of acquisition of equipment and machinery

Operational investment that included the cost incurred during production. These included:

- a) Quantities of inputs used in production

- b) Cost of inputs of production

- c) Payment of salaries and wages

- d) Costs of taxes, depreciation, permits and licenses

- e) Cost of acquisition of financing

Operational incomes that included:

- a) Products and production quantities

- b) Market price of products per unit value of product

For aquaculture investments, sensitivity can be analyzed by simulating changes (but not limited to) in:

- a) Produce prices

- b) Cost of feeds

- c) Production quantities

- d) Food conversion ratios and

- e) Survival rates of fish species under culture

It is important to point out that there are experts in aquaculture economics in Kenya who can do these analysis for potential investors. Unless the investors are themselves conversant with the analysis, they need not struggle to do them but consult the experts.

Enterprise budgeting

Commercial aquaculture can result in good profits but it can also result in meaningless gains or huge losses. The reasons for failure are diverse but include:

- Over-capitalization

- Improper practices

- Poor planning

- Lack of foresight

- Lack of hindsight

There is no need to start something that you do not know whether it will make intended gains. It is therefore important to find out in general terms, the costs and returns of the proposed aquaculture venture before investment is done. To do this, you need to do a budget of your enterprise to see how it will operate. An enterprise budget provides information on annual cost, annual returns and capital investment requirements for a particular enterprise. Many farmers budget in their heads and end up making wrong decisions. Good budgets should be written so that they can be reviewed as times goes by. Most of the information needed for a good budget is available locally e.g. past experience, farm plan, agricultural input dealers for input costs, aquaculture product dealers for fish prices etc.

Uses of an enterprise budget;

- It is used by Farm manger as a plan of operation before production

- Can be used as reference during production or after marketing

- It forms basis of a comparison of what really happened versus what was planned so as to inform on improvement

- Aid in cash flow planning, in controlling production costs and in determining the Break Even Prices and Yields

The basic structure of an Enterprise Budget consists of:

i) Gross Receipts

This refers to gross returns or total sales from the farm. It is the income generated from the sale of farm produce e.g. fish, fingerlings etc. They are estimated by multiplying the total expected harvest weight (quantity) with the expected price per unit weight (kg).

ii) Variable costs

This is also referred to as operating costs. These are costs that vary with production or expenses related directly to the quantity of fish produced for market.

All production costs/expenses are itemized and they include; Cost of fingerlings, feeds, labour, interest on operating capital etc.

Interest on operating capital is a variable cost and is a charged for a loan required to purchase production inputs

Total Variable costs (TVC) is the sum of all variable costs

iii) Fixed costs

These are costs that are incurred regardless of the level of production (operation). They include; depreciation, interest on investment capital and other costs not related to active production of the business e.g. insurance. They are also referred to as ownership costs.

| Depreciation refers to an expenditure allocated to a tangible asset's cost over its useful life. Depreciation is a non-cash expense and therefore it increases free cash flow while decreasing reported earnings. It is used in accounting to match the expense of an asset to the income the asset helps an investment earn. For example, if a farmer buys equipment for KShs 10,000 and expects it to have a useful life of 10 years, it will be depreciated over 10 years. Every year, the farmer will expense KShs 1,000 (assuming straight-line depreciation), which will be matched with the money that the equipment helps to make each year. Depreciation applies only to items that have a definable useful life. |

Total fixed costs is the sum of all fixed costs.

Net returns: This is the difference between gross receipts and total costs which is the indication of the amount of profit earned.

Returns above variable costs

- This is the difference between the GROSS RETURNS and the TOTAL VARIABLE COSTS.

- If this figure is positive, it means that all variable expenditures are covered and the enterprise is profitable at least in the short run.

- If they are negative, it is advisable to close the business if you can not reduce on the variable costs

Net returns

- This is the difference between the TOTAL COSTS and the GROSS RETURNS.

- Positive returns indicate that the enterprise is profitable even in the long term while negative returns indicate that the enterprise is not viable and should be abandoned if you cannot reduce on the costs.

Table 1: An enterprise budget for a hypothetical fully operational tilapia /catfish farm

- Farm size: 0.5 Ha

- Productivity: 3 kg/m2/year

- Av price of fish in KES/Kg: 250

| Item | Description | Unit | Unit price (KES) | Quantity | Total Amount |

| Gross Receipts | |||||

| Tilapia | Whole fish | kg | 200 | 12,000 | 2,400,000 |

| Catfish | Filet | kg | 300 | 3,000 | 900,000 |

| Gross Receipts | 3,300,000 | ||||

| Variable Costs (VC) | |||||

| Tilapia fingerlings | 1 month old | No. | 3 | 30,000 | 90,000 |

| Catfish fingerlings | 1 month old | No. | 5 | 10,000 | 50,000 |

| Wheat bran | kg | 30 | 35,000 | 1,050,000 | |

| Fertilizers | DAP | kg | 50 | 130 | 6,500 |

| CAN | kg | 50 | 270 | 13,500 | |

| Lime | kg | 20 | 1,300 | 26,000 | |

| Labour | Pond repairs and harvesting | KShs/day | 2000 | 150 | 300,000 |

| Interest on operation loan | KShs | 12% | 500,000 | 60,000 | |

| Total Variable Costs (TVC) | KShs | 1,596,000 | |||

| Net returns above TVC | KShs | 1,704,000 | |||

| Fixed Costs (FC) | KShs | ||||

| Depreciation | Ponds | KShs | 40,000 | ||

| Equipment | KShs | 10,000 | |||

| Machinery | KShs | 30,000 | |||

| Buildings | KShs | 10,000 | |||

| Water supply | KShs | 20,000 | |||

| Interest on capital investment | KShs | 30,000 | |||

| Total Fixed Costs (TFC) | KShs | 140,000 | |||

| TOTAL COSTS | KShs | 1,736,000 | |||

| Net returns above TC | KShs | 1,564,000 | |||

| Net returns/Ha | KShs/ha | 3,128,000 | |||

| Break Even Price | |||||

| Above TVC | KShs/kg | 106.4 | |||

| Above TC | KShs/kg | 115.7 | |||

| Break Even Yield | |||||

| Above TVC | kg/ha/year | 12,768 | |||

| Above TC | kg/ha/year | 13,888 |

Cash flow budget

One useful tool for planning the use of money in an aquaculture enterprise is a cash flow budget. A cash flow budget is an estimate of all cash receipts and all cash expenditures during a certain time period. Estimates are made monthly, bimonthly, quarterly or annually. Estimates can include non-farm income and expenditures as well as farm items. Cash flow budgeting looks only at money movement, not at profitability. Non-cash revenue or non-cash expenses, for example depreciation, are not considered.

A cash flow budget is a useful management tool because it:

- Makes you to think through your production and marketing plans for the year.

- Tests farming plans: will it be possible to produce enough income to meet all cash needs?

- Projects need for operating credit and ability to repay borrowed funds.

- Projects when to borrow money and when to repay.

- Helps in control of finances. By comparing the budget to actual cash flow, one can spot developing problems due to an unexpected drop in income or unplanned expenses, and opportunities to save or invest funds if net cash flow is higher than expected.

- Helps communicate farming plans and credit needs to lenders.

Items to be included in a cash flow budget include:

- Receipts from sales

- Operating cash expenses

- Living expenses

- Other expenses e.g. Personal withdrawals

- Debt interests and payments

- Capital sales

- Capital purchases

- Income tax payments

Each type of revenue is charged during the specific period when it is occurred.

Cash flows differ depending on the purpose for which the analysis is being developed. You could have:

- Monthly cash flow budgets - for detailed financial planning

- Quarterly budgets - to develop estimates of cash needs over a several year period

- Annual budgets - used in investment analysis to determine cash flow over the life of the investment

Components (items) of a cash flow budget

- Beginning cash balance (BCB) - this is the amount of cash at hand at beginning of the production period.

- Receipts - cash revenue generated by sales of the crop or capital assets.

- Note: cash revenue items (receipts) + BCB are summed up to obtain Total cash inflow for the time period

- Operating cash expenses - expenses related directly to the quantity of fish produced. e.g. fingerlings, feeds, field labour, security personnel, repairs etc.

Also expenses associated with the purchase of capital assets or breeding stock are included.

- Living expenses - this Includes what the owner of the enterprise spends on the self which can be referred to as nonfarm investments

- Other expenses - not related to actual production

- Scheduled debt payments - includes principal and interest payments for each separate loan.

Note: All expenses are summed to obtain total cash outflow.

- Cash available - this is the difference between Total cash inflow and total cash outflow

- New borrowing - if the cash available is negative, this means that there is insufficient cash generated during the period to meet all cash obligations and additional borrowing is needed for that time period.

- Cash balance - obtained by adding cash available to new borrowing. It becomes the beginning cash balance at the start of next time period. This must always be positive

- Debt outstanding - an accounting of the debt outstanding for each loan is kept at the bottom of the cash flow budget. Therefore, principal payments in a time can be subtracted out of the balance owed.

Table 2: An annual Cash Flow budget for a hypothetical fully operational tilapia /catfish farm

- Farm size: 0.5 Ha

- Productivity: 3 kg/m2/year

- Av price of fish in KES/Kg: 250

| Item | Yr 0 | Yr 1 | Yr 2 | Yr 3 | Yr 4 | Yr 5 | Yr 6 |

| Beginning cash Balance | 100,000 | 732,000 | 1,364,000 | 1,996,000 | 2,628,000 | 3,260,000 | |

| Tilapia | 2,400,000 | 2,400,000 | 2,400,000 | 2,400,000 | 2,400,000 | 2,400,000 | |

| Catfish | 900,000 | 900,000 | 900,000 | 900,000 | 900,000 | 900,000 | |

| Total Cash inflow | 3,400,000 | 4,032,000 | 4,664,000 | 5,296,000 | 5,928,000 | 6,560,000 | |

| Operating cash expenses | |||||||

| Tilapia fingerlings | 50,000 | 50,000 | 50,000 | 50,000 | 50,000 | 50,000 | |

| Catfish fingerlings | 900,000 | 900,000 | 900,000 | 900,000 | 900,000 | 900,000 | |

| Wheat bran | 1,050,000 | 1,050,000 | 1,050,000 | 1,050,000 | 1,050,000 | 1,050,000 | |

| Fertilizers | 6,500 | 6,500 | 6,500 | 6,500 | 6,500 | 6,500 | |

| 13,500 | 13,500 | 13,500 | 13,500 | 13,500 | 13,500 | ||

| Lime | 26,000 | 26,000 | 26,000 | 26,000 | 26,000 | 26,000 | |

| Interest on operation loan | 60,000 | 60,000 | 60,000 | 60,000 | 60,000 | 60,000 | |

| Total Operating cash expenses | 2,406,000 | 2,406,000 | 2,406,000 | 2,406,000 | 2,406,000 | 2,406,000 | |

| Living expenses | 100,000 | 100,000 | 100,000 | 100,000 | 100,000 | 100,000 | |

| Other expenses | 50,000 | 50,000 | 50,000 | 50,000 | 50,000 | 50,000 | |

| Scheduled debt repayments | |||||||

| Interest on Investment loan | 12% | 150,000 | 120,000 | 90,000 | 60,000 | 30,000 | |

| Repayment | 5 yrs | 250,000 | 250,000 | 250,000 | 250,000 | 250,000 | |

| Operating principle | 100,000 | 100,000 | 100,000 | 100,000 | 100,000 | 100,000 | |

| Interest on operation loan | 12% | 12,000 | 12,000 | 12,000 | 12,000 | 12,000 | 12,000 |

| Total Cash Outflow | 2,668,000 | 2,668,000 | 2,668,000 | 2,668,000 | 2,668,000 | 2,668,000 | |

| Cash available | 732,000 | 1,364,000 | 1,996,000 | 2,628,000 | 3,260,000 | 3,892,000 | |

| New Borrowing | |||||||

| Cash Balance | 732,000 | 1,364,000 | 1,996,000 | 2,628,000 | 3,260,000 | 3,892,000 | |

| Outstanding debts | |||||||

| Investment | 1,250,000 | 1,000,000 | 750,000 | 500,000 | 250,000 | 0.0 |

Commercial aquaculture species in Kenya

The following are the important commercial aquaculture species cultured in Kenya:

Nile tilapia (Oreochromis niloticus)

|

| Nile tilapia; max. length: 60 cm |

|

© Mbugua Mwangi, Kenya

|

- Tilapia are indigenous to Africa, but have been introduced in many parts around the world.

- They are disease-resistant

- They are prolific breeders and reproduce easily under culture conditions

- Feed on a wide variety of foods and tolerate poor water quality with low dissolved oxygen levels.

- Can grow in brackish water and some will adapt to sea water

- Mainly grow under semi-intensive systems as monoculture, males only monoculture or polyculture with African catfish

- Optimum temperature range 27 - 30°C

- Very popular in Kenya and have a good market in world

- Fillets yield is from 30% to 37%, depending on fillet size and final trim

African catfish (Clarias gariepinus)

|

|

| African catfish; average length: 1 - 1.5 m |

|

© Courtesy of Sagana Aquaculture Centre Kenya

|

- Indigenous to Africa.

- Can be described as omnivorous eating vegetable matter, zooplankton, insects, snails, tadpoles, leeches, small fish etc.

- Very hardy and can survive in low oxygen waters

- Can grow in brackish water in salinities of 10ppm

- Has ability to breath atmospheric oxygen

- Do not breed in captivity and artificial spawning is used

- Grows very quickly if adequate high protein feed is available.

- Few bones; has higher fillet percentage than tilapia

- Mainly grown in semi-intensive polyculture systems with tilapia

- Optimum temperature range 25 - 27°C

A good candidate for rural aquaculture in developing countries

Rainbow trout (Oncorhyncus mykiss)

|

|

| Rainbow trout; average length: 51 - 76 cm |

|

© Mbugua Mwangi

|

- Native of North America but has been introduced and farmed all over the world

- A carnivorous fish which in natural waters consumes insects, crustacean and other small animals

- Grows well in cool fast flowing waters, 10 - 18°C, with high oxygen content

- Under culture conditions, require a water flow rate of 1 l/min/kg without aeration

- Trout will not spawn naturally in aquaculture systems and artificial spawning is used

- Produced in intensive systems in tanks and raceways

- Restricted to highland areas in tropical regions where favorable conditions allow

- Requires high quality feed, >40% protein.

- High market price, especially when fresh

- Fine bones; high fillet percentage and excellent when smoked.

Common carp (Cyprinus carpio)

|

| Common carp; max length: 1.5 m |

|

© Courtesy of Sagana Aquaculture Centre Kenya

|

- An exotic species that has established itself in natural water bodies in Kenya

- An omnivore feeding onorganisms in mud at pond bottom, makes the pond water muddy.

- Eats a variety of supplementary foods including bran.

- Very limited aquaculture production in Kenya where they are grown under semi-intensive systems

- Attains a large size and does not usually overpopulate a pond.

- Optimum temperature range, 23 - 26°C

- Poor market in Kenya due to intramuscular bones but popular in Asia.

Farming Tilapia

Biological characteristics of tilapia

Tilapia is the generic name of a group of cichlids endemic to Africa. The important aquaculture genera in Kenya are Oreochromis, and Tilapia. All tilapia species are nest builders; fertilized eggs are guarded in the nest by a brood parent. Sarotherodon and Oreochromis are mouth brooders; eggs are fertilized in the nest but parents incubate them in their mouths including several days after hatching. For the Oreochromis, only females practice mouth brooding, while in Sarotherodon, either the male or both male and female mouth brood.

|

| Nile tilapia |

|

© Mbugua Mwangi, Kenya

|

Tilapia farming involves the culture of following species:

i. Oreochromis niloticus

ii. Oreochromis mossambicus

iii. Oreochromis aureus

iv. Oreochromis spilurus

v. Oreochromis andersonii

vi. Tilapia zillii.

vii. Tilapia rendalli

Feeding Habits

Tilapias are heterogeneous in their feeding. They and have ability to consume and efficiently assimilate a wide variety of foods. Various species are omnivorous; others are phytoplanktonous while others are macrophyte feeders.

- Omnivorous are: O. mossambicus, O. niloticus, O. spilurus, O.andersonii and O. aureus.

- Phytoplankton feeders: O. leucostictus, O. macrochir, O. esculentus, O. alcalicus grahami, and S. galilaeus

- Macrophytes (feed on larger plants) feeders: T. rendallii and T. zillii.

Maturation

In natural water bodies, tilapias mature in about two to three years. Under culture they tend to mature early. Sexual features distinguishing males from females are clear when fish mature (about 15 cm in Tilapia zillii and 10 cm in Oreochromis niloticus). Males have two orifices situated near the ventral (anal) fin, one is the urinogenital aperture and the other is the anus. The females have three orifices, the genital opening the anus and a urinary orifice (but difficult to visualize with the naked eyes). Separation of males and females can be made easier by applying dye (India ink, indigo, etc.) to the papilla with a cotton swab to outline the male and female openings.

Fecundity

Fecundity refers to the number of eggs produced by a fish in a spawn. This applies well for monocyclic species, that is, once a year breeders. Tilapias are polycyclic (many times breeders) and their ovary may contain eggs at different stages of maturity.

In substrate brooding (nest building) tilapias, fecundity is much higher than mouth brooders. Other characteristics that differentiate substrate brooders (Tilapia) and mouth brooders (Oreochromis) are:

| Characters | Tilapia | Oreochromis |

| Fecundity | high | low |

| Egg diameter (mm) | 1-1.5 | up to 5.0 |

| Yolk percentage | less than 25% | up to 45% |

| Yolk colour | pale yellow | orange |

| Size of fry at feeding | 5-6 mm | 9-10 mm |

| Courtship | prolonged (monogamous) | brief (polygamous) |

| Juvenile mortality | high | low |

| Longevity | up to 7 years | over 9 years |

Environmental requirements

Optimal Temperature

Temperature affects fish distribution, survival and growth, rate of development, reproduction and even susceptibility to diseases. Various species and strains of tilapia differ in tolerance to low temperatures, but growth is generally limited at water temperatures below 16°C and most become severely stressed at 13°C. Death occurs from 12°C with few surviving temperatures below 10°C. Most will not feed or grow at water temperatures below 15°C and will not spawn below 20°C. The normal water temperature should be between 20 to 30°C. Metabolic rate rises at higher temperatures which lead to death.

Optimal Dissolved Oxygen (DO)

Tilapias are able to tolerate low levels of ambient oxygen. Usually, well fertilized ponds will have low levels of oxygen early in the morning. Night activities are dominated by respiration and decomposition which reduce DO. Larger fish are less tolerant than juveniles. This could be due to the difference in their metabolic demand. The optimal DO for tilapia culture is 4 mg/litre (50%) and should not go below 2.3 mg\litre.

Salinity

The Nile tilapia is the least saline tolerant of the commercially important species, but grows well at salinities up to 15 ppt. The Blue tilapia grows well in brackish water up to 20 ppt salinity, and the Mozambique tilapia grows well at salinities near or at full strength seawater

pH

Tilapia can survive in pH ranging from 5 to 10 but do best in a pH range of 6 to 9.

Ammonia

Massive tilapia mortality will occur within a few days when the fish are suddenly exposed to water with unionized ammonia concentrations greater than 2 mg/l Prolonged exposure (several weeks) to un-ionized ammonia concentration greater than 1 mg/l causes deaths, especially among fry and juveniles in water with low DO concentration.

Nitrite Nitrite is toxic to many fish and chloride ions reduce the toxicity. Tilapia are more tolerant to nitrite than many cultured freshwater fish. In general, for freshwater culture the nitrite concentration should be kept below 27 mg/l.

TILAPIA FARMING

Pond culture is the most popular method of growing tilapia. They are grown in fertilized ponds where the fish utilize natural foods from ponds. Management practices of the systems ranges from extensive; using only organic or inorganic fertilizers, to intensive systems, using high-protein feed, aeration and water exchange. The major problem to overcome in this system is the prolific breeding of the fish that occur in ponds under mixed sex culture. This breeding if not controlled results to overcrowding in the ponds. The end result is stunted growth yielding small size fish (less than 100 g) which may not be of market value. In mixed-sex populations, the biomass of juveniles can make up to 70 percent of the total harvest weight. Therefore strategies for producing tilapia in ponds should aim at controlling spawning and recruitment.

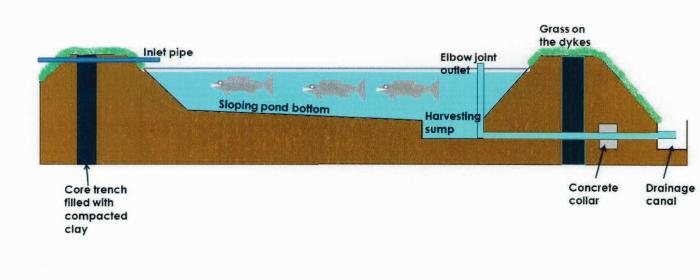

For easy management and economical operation in Kenya, grow out ponds should be about 1 to 2 metres deep and at least 300 sq metres for semi-intensive production of tilapia. A harvesting sump in the pond behind the drainage outlet is needed to concentrate the fish in the final stage of drainage. The pond should be drained completely and be allowed to dry to eradicate any fry or fingerlings that may interfere with the next production cycle. This will also kill some parasites, frogs' egg and other unwanted organisms that may be in the ponds.

Mixed-sex culture

Under mixed-sex culture of tilapia, both males and female are cultured together but harvested before or soon after they reach sexual maturity. This minimizes chances of recruitment and overcrowding. The disadvantage in this is that fish are harvested at a smaller size due to the limited growth period. In this culture practice, fish are usually stocked at low rates to reduce competition for food and promote rapid growth. One month-old, 1-gram fry are stocked at 1 to 2 per square meter and grown for about 4 to 5 months. In cold areas where the water temperatures are low and therefore growth is slow, tilapia might not reach marketable sizes in that period.

Newly-hatched fry should be used all the time because older ones will reach sexual maturity at a smaller, unmarketable size. They could also be mature fish but stunted. Supplemental feeds with 25 to 32 percent protein are generally used. The average harvest weight is about 250 g and total production about 0.25 kg/sq m for a stocking rate of 1 fish/m2. Higher stocking densities can be employed to achieve higher production but must be combined with very good management. Expected survival is about 80 percent.

Species such as Tilapia zilli, T. hornorum, or T. mossambica are not suitable for mixed-sex culture because they reach reproductive maturity at 2 to 3 months at an unmarketable size of about 30 grams. Those that are suitable for this culture are O. nilotica and O. aurea which reach reproductive maturity at 5 to 6 months. Two to three crops of fish can be produced annually in Kenya depending on the water temperatures.

Mono sex culture

To overcome the problem resulting from prolific breeding of tilapia, ponds are stocked with males only because the males grow almost twice as fast as females. Male fingerlings can be obtained by three methods:

- Hybridization

- Sex-reversal and

- Manual sexing.

None of these methods is 100 percent effective, and a combination of methods is recommended. Hybridization can be used to produce better results of males only. The hybrids can then be subjected to hand sexing and/or sex-reversal treatment. Sex-reversal requires obtaining recently hatched fry and rearing them in tanks or hapas where they are subjected to hormone laced feed for about three weeks.

Hormonal sex reversal needs a tank-based or hapa-based hatchery that will allow fry to be collected at the yolk sac or first feeding stages (no later than one week after they have been released from the female). The healthy fry of uniform size are transferred to the tank or hapa where you will feed them with hormone-laced diet for 21-28 days. The feed is prepared as follows:

- Mix 30 - 70 mg of hormone (methyl or ethynyl testosterone) in 700 ml of 95% neutral ethanol

- Add 700 ml of hormone solution to each kg of finely ground feed then mix thoroughly and dry. At this stage you may add any needed supplements

- This feed should be kept under refrigeration if it is not going to be used immediately

- Feed the fry at a rate of 10 - 30% of body weight per day, at least four times a day for 21 - 28 days.

- The fry must eat this feed to sex-reverse

This is not in accordance with the organic principles and therefore cannot be applied.

Manual sexing (hand sexing) involves separating males from females by visual inspection of the external urinogenital openings. Reliability of manual sexing depends on the skill of the workers, the species to be sorted and fish sizes. Experienced workers can easily sex 20-gram fingerling T. hornorum and T. mossambica, 30-gram T. nilotica, and 50-gram T. aurea. Tilapia males are preferred for culture because they grow faster than females. Females use considerable energy in reproduction and do not eat when they are incubating eggs. All-male culture permits the use of longer culture periods, higher stocking rates and fingerlings of any age. High stocking densities reduce individual growth rates, but yields per unit area are greater. If the growing season can be extended, it should be possible to produce fish of up to 500 grams. Expected survival for all-male culture is 90 percent or greater.

Females included in a population of mostly male tilapia affects the maximum attainable size of the original stock in grow-out. A stocking rate of 2/m2 is commonly used in Kenya to achieve yields of 1kg/ m2. At this stocking rate the daily weight gain will range from 1.5 to 2.0 grams. Culture periods of 6 months or more are needed to produce fish that weigh close to 500 grams. There are cases in Kenya where stocking densities of 6 juveniles/ m2 is practiced with a production of up to 3kg/m2. Higher stocking densities will require water aeration and sub-optimal feeding rates may have to be used to maintain suitable water quality.

Polyculture

In Kenya tilapia are frequently cultured with other species, mainly catfish (Clarias gariepinus) to take advantage of many natural foods available in ponds and to produce a secondary crop, or to control tilapia breeding. Polyculture uses a combination of species that have different feeding niches to increase overall production without a corresponding increase in the quantity of supplemental feed. Polyculture can improve water quality by creating a better balance among the microbial communities of the pond, resulting in enhanced production.

Other possible polyculture combinations that can be done in Kenya include:

- Tilapia and prawns (Macrobrachium rosenbergii): In this case, survival and growth of tilapia and prawns are independent. Feed is given to meet the requirements of the fish. Prawns, which are unable to compete for the feed, utilize wasted feed and natural foods that result from the breakdown of fish waste.

- Tilapia and large mouth bass (Micropterus salmoides): The bass which is carnivorous, control the breeding of tilapia in mixed sex culture. This allows the original stock to attain a larger market size. Predators must be stocked at a small size and percentage to prevent them from depleting the tilapia stock.

Fertilization and manuring

Where the natural pond productivity is enhanced through water fertilization, reasonable production can be achieved without exogenous feeding. Although yields will be lower than those obtained with exogenous feeding, fertilization will reduce the quantity and expense of feeding. Application of an inorganic fertilizer high in phosphorus should be done prior to stocking fish to create an algal bloom. Tilapia productivity is stimulated mainly by an increase in phosphorus and to a lesser extent by an increase in nitrogen. The inorganic fertilizers used in Kenya are DAP (Diammonium phosphate) and CAN (Calcium ammonium nitrate) and are not allowed in organic fish farming, while animal manure is allowed.

Animal manure is widely used in Kenya in fish production in earthen ponds. The quality of manure as a fertilizer varies depending on the source animal and the quality of feed fed to the animal. Pig, chicken and duck manures increase fish production more than cow and sheep manure. Animals fed high quality feeds (grains) produce manure that is better as a fertilizer than those fed diets high in crude fibre. Fine manures provide more surface area for the growth of microorganisms and produce better results than large clumps of manure. The manure should be composted before being used in the fish pond. It spreads easier and does not take oxygen from the water for the process of composting while minerals are kept in the material during composting

Manure should be distributed evenly over the pond surface area. Accumulations of manure on the pond bottom produce low oxygen conditions (during decomposition) in the sediment resulting to reduced microbial activity and sometimes result in the sudden release of toxic chemicals into the water.

|

| Manure crib |

|

© Mbugua Mwangi, Kenya

|

Methods of applying manure

- Crib method: A compost crib constructed using wooden sticks at one or more sides of the pond. It helps fertilize the water gradually. The manure in the crib requires frequent turning to facilitate the release of nutrients.

- Bag method: A bag is filled with manure and tied to the corner of the pond. The bag is shaken weekly or daily to release nutrients.

Manure application rates for ponds

Manure application rates depend on the size of the pond, which is expressed as surface area of the water in the pond. The recommended rate is 50 g of dry matter per m2 per week i.e. 5 kg/100 m2/week.

The maximum rate depends on the quality of the manure, the oxygen supply in the pond and water temperature. If early morning DO is less than 2 ppm, manuring should be reduced or stopped until DO increases. When water temperatures are less than 18° C, manure application should be discontinued. At low temperatures the rate of decomposition decreases and manure may accumulate on the pond bottom. A subsequent increase in temperature could then result in oxygen depletion.

Agricultural Lime

- Used to improve soil quality, which helps the organic and chemical fertilizers to work better. It also helps to clear up muddy water.

- In red soils; about 20 kg per 100 m2 can be applied. Black cotton soils may require a little more.

Some characteristics of organic and chemical fertilizers

| Allowed in organic fish farming: Organic (farm manure) |

Not allowed in organic fish farming: Chemical: DAP, Urea, MAP, TSP |

| Contains trace minerals and vitamins. | Contains only what the label says |

| Uses oxygen to decompose. | Does not use oxygen when dissolving |

| Is highly variable in composition depending on feeds given to the animals and bedding used | Varies little in composition from what is indicated on the label. |

| Can help reduce turbidity due to clay silt in the ponds | Does not reduce turbidity |

| Can help reduce seepage in ponds | Does not act on seepage |

| Some of the ingredients can be consumed directly by the fish | Not directly consumed by the fish |

Integrated systems

|

| Tilapia and Catfish farming integrated with poultry |

|

© Mbugua Mwangi, Kenya

|

Manure application can be made easy by placing animal production units adjacent to or over the fish ponds so that fresh manure can easily be delivered to the pond on a continuous basis. This also allows the feed wasted by the animals to fall into the fish pond and utilised by the fish. Effective and safe manure loading rates are maintained by having the correct number of animals per pond surface area.

Chicken/fish farming

Maximum tilapia yields are obtained from the manure output of 5,000 to 5,500 chickens/ha, which deliver 100 to 113 kg (dry weight) of manure/ha/day. Several crops of chickens can be produced in one fish production cycle.

Duck/fish farming

|

| Pig house with fish pond |

|

© Stephen Gikonyo, Kenya

|

Ducks are grown on ponds at a density of 750 to 1500/ha. The ducks are raised in confinement, fed intensively, and allowed a small portion of the pond where they forage for natural foods and deposit their manure. Ducks reach marketable size in 10 to 11 weeks and therefore staggering production cycles is needed to stabilize manure output.

Pig/fish farming

|

| Pond harvesting using a sein net |

|

© Mbugua Mwangi, Kenya

|

Approximately 60 to 70 pigs/ha are required to produce a suitable quantity of manure (100 to 115 kg of dry matter/ha/day) for tilapia production. The pigs are usually grown from 20 to 100 kg over a 6-month period. In certain cultures and religion, where pigs are considered unclean, used of pig manure might reduce the marketability of the fish.

Further information on how to integrate animal production with fish culture under www.agromisa.org

Harvesting

Fish produced for consumption should be harvested when they reach market size. In Kenya, tilapia are ready for harvesting within six to nine months depending on the size at stocking, target harvest size, water temperature and level of management employed. The time of harvesting is determined through regular sampling which should be done monthly. A day or two before harvesting, feeding and fertilizer application should be stopped. During harvesting:

- Fish should be checked for off flavours

- Fish should be harvested during cool weather

- Harvesting and transportation equipment should be set up well in advance to ensure reduced stress and minimal fish mortality.

Tilapias are best harvested by seining for partial harvesting and complete drainage for complete harvesting. Once harvested, fish should be handled with care and transported to the market while still fresh.

Growth and yields

Under proper management and optimal conditions, 1-gram fish are cultured in nursery ponds to 20 to 40 grams in 5 to 8 weeks and then stocked into grow-out ponds. In mono-sex, males can reach 200+ grams in 4 to 5 months, 400 + grams in 5 to 6 months, and 500+ grams in 8 to 9 months. Dress-out percentage on tilapia is low compared to species such as trout and catfish. Tilapias have a dress-out of 51 to 53 percent of live weight for whole-dressed fish (head-off) and 32 to 35 percent for filets.

Diseases

Tilapias are more resistant to viral, bacterial and parasitic diseases than other commonly cultured fishes. Few diseases and mortalities have been reported in semi intensive tilapia farms in Kenya. This could due to low stocking densities in these systems. Lymphocystis, columnaris, whirling disease, and hemorrhagic septicemia may cause high mortality, but these problems occur most frequently at water temperatures below 11°C. The most important cause of mortalities is anoxia resulting from blooms of algae. Sudden lowering of temperatures to below the tolerance levels, which can happen during the rainy seasons, can lead to problems including mortalities.

Hatchery Management and Tilapia Fingerling Production

Although tilapia breed freely in ponds, it is important for farmers (producers) to consider using properly produced fingerlings. They need to invest in hatcheries for fry and fingerling production. Quality fingerlings in tilapia aquaculture are very important. For this reason it is advisable for farmers to generate their own fingerlings if they can not ascertain the quality of those from other sources. Poor fingerlings result in poor harvests.

Developing a hatchery will allow the farmer to have ready fingerlings whenever he needs them. As long as the demand for fingerlings exists, a well-managed hatchery can turn out to be a good business.

Three methods of tilapia fingerlings production are commonly practiced in Kenya:

- open ponds (most commonly used)

- tanks

- hapas in ponds (net enclosures)

For these methods, fry are collected from the spawning units and stocked into fertilized ponds for rearing to the fingerling stage before they are stocked into grow out ponds.

Open pond method

|

| Poorly constructed earthen ponds |

|

© Mbugua Mwangi, Kenya

|

This is the simplest and most common method of tilapia fingerling production in Kenya. A properly constructed and well fertilized pond serves both for breeding and rearing fry. Brooders are stocked into the ponds and allowed to spawn naturally. The brood fish are stocked at the rate of 100 to 200 kg/ha at a sex ratio of 1:3 or 1:4 (males to females). A female brood fish of 90-300 g produces as much as 500 eggs per spawning. They should produce 6 - 15 fry/m2/month. To increase seed production, use larger brooders. Brooders of 1 - 1.5 kg can produce 45 fry/ m2/month. For this case, you need to harvest every 17-19 days.

Harvesting fry from the ponds is done every 15 - 21 days or more frequently with water temperatures above 25°C). The brooders can be used for 3 - 5 years. Fry harvesting should be done by hand scoop nets along the edges of the pond to minimize pond disturbance and fry mortality.

The tank method

|

|

Circular tanks for a trout hatchery |

|

© Mbugua Mwangi, Kenya

|

Tank-based hatcheries are relatively expensive to set up. The tanks should be circular in shape and can be made of concrete, plastic, fiberglass or even metal. The tanks should be 1-6 m diameter with a water depth of 0.5-1 m. Diet should contain 30-40% crude protein and daily supply at 1-2% of body weight. Fry can be collected every 10 – 14 days. Yields of up to 400-3,000 fry/m2/month can be realized using this method. Tanks are easy to manage but are relatively expensive to set up compared to ponds and hapas.

The 'hapa' method

A hapa is a cage like net impoundment placed in a pond for holding fish for various purposes. They are made of fine mesh netting material. The mesh size is such that the fry or fish inside can not escape. The ideal hapas is 3 m long, 3 m wide, and 1.5 m deep. When using hapas to generate fingerlings, stock brooders should be weighing about 100 to 200 g at a ratio of about 1:5 to 1:7 males to females. Stock the brooders at a density of 4 - 5 brooders / m2. Hapas should be inspected for fry every day. Remove the fry using a scoop net after two week and stock them into tanks, other hapas, or in a rearing pond. Fry-production in hapas range from 150 to over 880/ m2/month. Fry should be fed 4 times/day until the fry reach the desired size (5 g). Use a diet in powder form at the rate of 5-10% of the total body weight per day

|

| Breeding hapas in a fish pond |

|

© Mbugua Mwangi, Kenya

|

Production in hapas range from 150 fry/m2/month to over 880 fry/ m2/month.

|

| Inspecting tilapia breeding hapas |

|

© Mbugua Mwangi, Kenya

|

Feeding

Advantages of using this method are easy handling of fry ad brooders, a high production per unit, uniform fry of the same age, minimal losses and hapas can be set up in a pond with other fish.

Disadvantages of the hapa method tha it is more demanding than open ponds and tanks, mortalities may occur due to agressiveness during spawning, the fish has to be fed, poor water quality is likely due uneaten feed and fish waste and mesh will get clogged limiting water circulation and need periodic scrubbing. In stormy weather hapas can be destroyed and the material will degrade in sunlight and need replacing. Fish may easily escape from damaged hapas.

Disadvantages of the hapa method

- Management is more demanding compared to the other methods

- Mortalities may occur due to agressiveness during spawning

- Feeding is a must

- Hapas can be destroyed during stormy weather

- Hapa material will degrade in sunlight and need replacing

- Fish may easily escape if the hapa is damaged

- Localised poor water quality is likely due uneaten feed and fish waste

- Hapa mesh will get clogged limiting water circulation and need periodic scrubbing

Production of all-male fingerlings (link to mono sex culture)

Pond design and construction for semi-intensive aquaculture

The importance of proper designs, construction and the need for involvement of experts during the process of setting up aquaculture production units is paramount. Ideally, production units should be designed in such a way to allow total control of:

- What gets in or out

- When it gets in or out

- How it does this

- How much gets in or out

- Rate of getting in or out

The production site is of great importance. It does not only dictate the fish species to be produced but also important, the cost of construction is directly related to the nature and location of the site. A good site should therefore meet the following criteria:

- Have water in quantity and quality needed for the proposed production. Not in a pollution prone area.

- Suitable topography to allow cost effective setting up the proposed production facility and have adequate room for possible future expansion

- Have soil suitable for pond construction (if ponds are planned).

A simple test of the suitability of a soil for pond construction:

- Dampen a handful of soil with water. Use only enough water to dampen the sample (do not saturate it).

- Squeeze the sample tightly in your hand.

- Open your hand:

- If the sample keeps its shape, it is probably good enough for building a pond (sufficient clay present).

- If the sample collapses and does not keep its shape, it is probably not good enough for building a pond (too much sand present)

- The site be in a region or area that is suitable and allowed for aquaculture production

- Well drained and away from flood-prone areas or at least having potential for flood control

- Allow for acceptable effluent disposal as required by environmental management authorities

- Have a climate suitable for production of the intended species

- Have accessibility to a good and all-weather market

- Have easy access to services and technical assistance

The final size of a fish farm is determined by: Amount of water available, the target production and the available capital. Intensive systems require less land compared to semi-intensive systems, to produce the same quantity of fish but require more capital to invest.

The number, size and the shape of ponds will be determined by:

- Topography of the land and the shape and size of the land. Rectangular ponds are easier to manage

- Intended use of the pond. Fingerling ponds should be smaller than fattening ponds.

- The species to be produced

- Frequency of harvest

- Target quantity per harvest

- Whether juvenile production is intended etc.

Pond design

Once the site has been identified, surveyed and the producer has made decision on the number and sizes of ponds that will be needed when the farm is fully operational, it is time to make a decision on the design of the ponds.

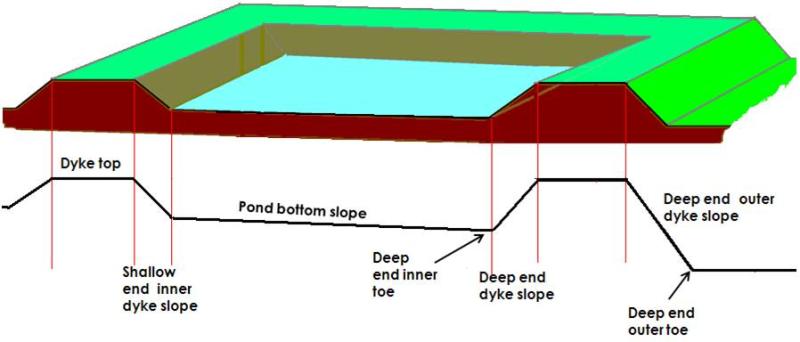

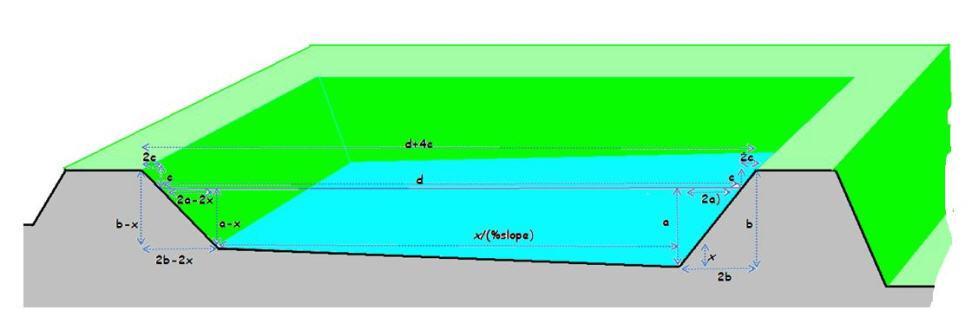

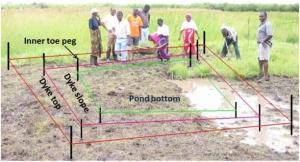

During the process of designing ponds, decisions on the following should be made:

- Total area of the pond water surface (this is the actual pond size)

- The length and the width of the pond water surface

- The water depth and the total pond depth at the deep end

- The slope of the dykes and the pond bottom

- The size of the free board (height of dyke above water level)

- The width of dykes

|

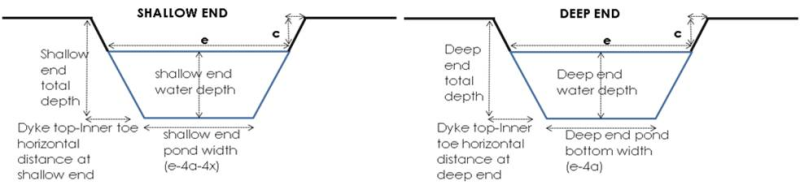

| A cross section on an earthen fish pond showing the slopes and the dykes |

Once this is done, all other pond dimensions can be calculated. The diagram below gives the relationships between various pond dimensions.

Calculations for the following design are based on the assumptions that:

- Dyke slope: 50% (0.5)

- Bottom slope: 1% (0.01)

Based on the above, the following apply:

|

| Pond designed to take maximum advantage of the winds |

|

© Mbugua Mwangi

|

| Total pond length | d+4c |

| Total pond width | e+4c |

| Shallow end water depth | a-x |

| Shallow end total depth | b-x |

| Shallow end bottom width | e-4a-4x |

| Deep end bottom width | e-4a |

| Dyke top-Inner toe horizontal distance at deep end | 2b |

| Dyke top-Inner toe horizontal distance at shallow end | 2b-2x |

|

| Cross section of pond |

|

© Mbugua Mwangi

|

|

|

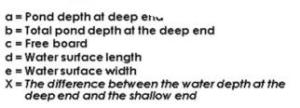

| Three-dimensional pond design |

|

© Mbugua Mwangi

|

Steps in the construction

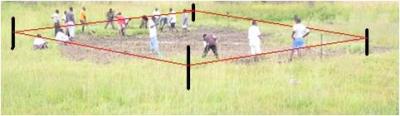

Step 1. Mark out the area that the pond will occupy using wooden pegs and strings and then remove all the vegetation.

|

| Clearing vegetation from the pond site |

|

© Mbugua Mwangi, Kenya

|

Step 2. Remove the top soil and keep it in a good location close to the site. It will be used to cover the pond bottom and the dyke tops to enhance fertility. Remember that if the soil is kept far away, this will increase the cost of pond construction since the soil will need to be brought back.

Step 3. Clear the area within the pond limit of all vegetation including the area within 10 m of dykes and pond structures and any access, water supply or drainage area.

Step 4. Establish a Temporary Bench Mark (TBM). A bench mark is a mark on the ground that establishes the elevation of a place and is used as a reference point for all other elevation. This will allow you to determine and check by use of leveling equipment (e.g. spirit level) the elevations of the dykes, canals and other structures. The Temporary Bench Mark should be set and permanently fixed in a protected location during the whole construction period.

Step 5. Using spirit level, measuring tape, pegs and strings, mark out:

|

| A site pegged ready for digging and filling |

|

© Mbugua Mwangi, Kenya

|

- The dykes

- Dyke slopes

- Inner and outer toes

- The pond bottom

Step 6. Using the determined pond depths and the actual elevations of the site, determine which areas need digging and which need filling. This is very important because it eliminates unnecessary movements of soil and thus keeps the construction cost at a minimum.

Step 7. Dig out the soil at the 'dig' areas and place it on the 'fill' areas. Most of the fill areas will be on the dyke position.

|

| Dig the soil from the dig areas and move it to the fill areas |

|