Short description: different sources of water for irrigation, components of drip irrigation kit and othe small scale irrigation systems.

Introduction

1) Deep ground water can be pumped from deep bore holes but is usually unsuitable for irrigation because of minerals in the water as well as high drilling and operational costs.

2) Shallow ground water can be delivered by

- hand pumps

- foot pumps

- small petrol pumps

- From lakes, rivers, hand dug wells and ground tanks to

to either elevated tanks from where water is gravitated to the fields, or water can be gravitated directly from the pump onto to the fields. Where the water source is situated at a higher elevation than the field to be irrigated, water can flow by gravity. A siphon pipe can lift water over higher elevated sections.

3) Surface water in streams, rivers and canals can be delivered by gravity in some circumstances. The water can be applied to crops by either:

i overhead sprinkler

ii drip irrigation by perforated pipes

iii furrow irrigation in open ditches

iv basin irrigation in flat plots of lands surrounded by soil bounds

v bucket irrigation is simply irrigating using a bucket with water.

4) Macro catchments consist of diverting rainwater run-off from external catchments, such as

i rock outcrops

ii hillsides

iii roofs and

iv roads by gravity to fields situated at a lower elevation than the catchment areas, by means of :

i garlands of stones on rocks

ii ditches along roads, gutters on roofs

iii soil bunds

iv cutoff drains on fields.

Fields can be irrigated with water from macro catchments using:

i uncontrolled flooding whereby fields are flooded unevenly all over

ii furrow irrigation in open ditches dug between rows of crops

iii basin irrigation in flat plots of land surrounded by low earth bunds

iv drip irrigation by perforated plastic pipes

Water from macro catchments can also be diverted into ground tanks and earth dams.

5) Micro catchments are shallow basins where rainwater runs from the upper part into the lower part of the basin where crops and trees are planted. Micro catchments can be:

i trenches

ii half moon basins

iii V-shaped basins

iv diamond-shaped basins

v trapezoidal basins

vi contour bund basins with tied ridges

A common feature of all the shapes is that surplus water in the basins passes safely over their spillways and into the micro catchments situated further downstream in the field.

Smaller means of irrigation are:

i Smaller means of irrigation are called: Zai pits

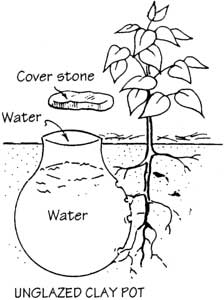

ii Clay pot irrigation, whereby water is poured into clay pots buried up to their necks in the ground

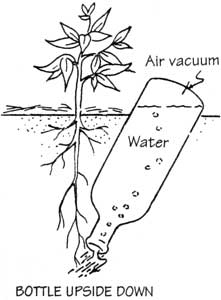

iii Bottle irrigation, by which bottles filled with water are buried upside down near a plant or tree

7) In situ storage is to store rainwater in the voids between soil particles where the rain falls. The technique complements soil conservation because the practice conserves and improves the soil structure to the effect that more crops can be grown on less rainfall. The types of structures are called:

i grass strips

ii trash lines

iii tied ridges

iv level bunds

v graded bunds

vi bench terraces

Drip irrigation

|

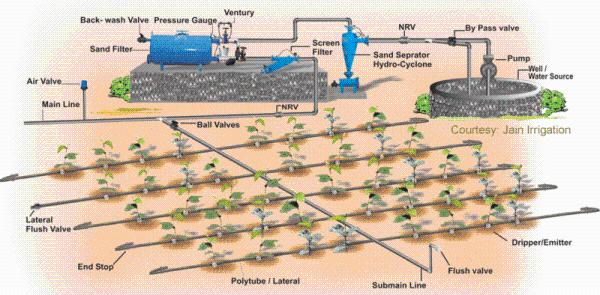

| Schematic of a typical commercial drip irrigation system. |

|

(c) Jain irrigation

|

Components

1) Pump or pressurized water source

2) Water filter(s) - filtration systems: sand separator, cyclone, screen filter, media filters

3) Fertigation systems (venturi injector) and chemigation equipment (optional)

4) Backwash controller

5) Main line (larger diameter pipe and pipe fittings)

6) Hand-operated, electronic, or hydraulic control valves and safety valves

7) Smaller diameter polytube (often referred to as "laterals" or "tapes")

8) Poly fittings and accessories (to make connections)

9) Emitting devices at plants (ex. emitter or drippers, micro spray heads, inline drippers)

System management

Small-scale drip irrigation systems

Bucket system

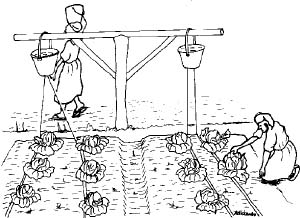

|

| Drip irrigation system |

|

© S. Fontana, Kenya

|

|

| Bucket drip irrigation system (IIRR) |

|

© Mail sent to IIRR

|

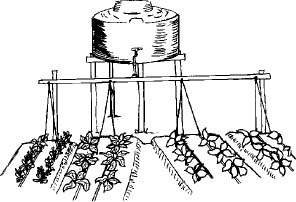

Drum system

Bucket systems are produced by Chapin Watermatics Inc, 740 Water St, Watertown, NY 13601, USA, and are distributed at low cost. Bucket, drum, one-eighth-acre garden, and orchard kits are currently being promoted and available from the Kenya Agricultural and Livestock Research Organization (KALRO), Nairobi.

Bamboo tube system

|

| Drum drip irrigation system (IIRR) |

|

© Mail sent to IIRR

|

|

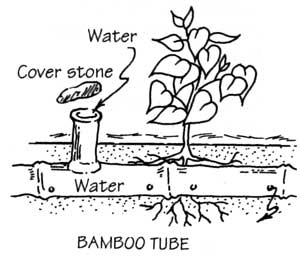

| Irrigation with a bamboo tube (Vukasin et al. 1995) |

|

(c) Natural Farming Network 1995

|

Pulsed systems

Others: Pitcher irrigation, Irrigation using a bottle

Pitcher irrigation

In order to achieve an effective irrigation, unglazed earthenware or clay pots are buried to the neck of the vessel next to plants or small trees. The pots are filled with water and covered with a lid. Since the unglazed walls of the pods are porous, the water can seep slowly out and reach the roots of the plants. Instead of a clay or earthenware pod, also the sweet monkey orange fruit (Strychnos spinosa can be used when it has been dried and the top cut off.

|

| Pitcher irrigation using an unglazed clay pot (Vukasin et al. 1995) |

|

© Natural Farming Network 1995

|

Irrigation using a bottle

A filled, open bottle can be placed with its neck into the soil next to a plant, so it stands upside down. The dense soil hinders the water from leaving the bottle immediately. Instead, it gets released slowly and directly besides the roots, so it is available to the plant for a longer time and the water cannot evaporate directly.

|

|

Small-scale irrigation using a bottle (Vukasin et al. 1995) |

|

© Natural Farming Network 1995

|

Information Source Links

- Clinton C. Shock (2006). Drip irrigation: an introduction. Malheur Experiment Station, Oregon State University. Available at www.cropinfo.net. Accessed on 30.03.2007.

- FAO. Small-scale irrigation for arid zones. www.fao.org

- International Institute of Rural Reconstruction (IIRR). Sustainable Agriculture Extension Manual. Available at www.iirr.org. Accessed on 30.03.2007

- Sijali, I. V. (2001). Drip irrigation. Options for smallholder farmers in eastern and southern Africa. RELMA Technical handbook No. 24. Nairobi, Kenya. ISBN 9966-896-77-5

- Vukasin H. L., Roos L., Spicer N., Davies M. (1995). Production without Destruction. Natural Farming Network. Zimbabwe.

- Water for Arid Land: www.waterforaridland.com

- Wikipedia: Drip irrigation. Available at www.wikipedia.org. Accessed on 30.03.2007.