|

Bacterial blotch (Pseudomonas tolaasi) The main source of bacterial blotch in the mushroom farm is the casing soil. The disease is favoured by dampness [high humidity (over RH 85%), high temperatures (over 20°C ) and poor ventilation in the growing houses]. It can be spread by the workers' hands, irrigation water and on the inventory. Mushroom flies and mites also spread the disease. The first disease symptoms appear in areas of caps that have been moist for a longest time and areas where mushroom caps touch. Symptoms include spots that darken becoming chocolate-brown in colour and slimy. It can also cause distortion and splitting of the stipes. When the infection is severe, spots spread throughout the whole mushroom surface. Seriously diseased mushrooms can become deformed and the caps can decay giving a foul (unpleasant) odour. Young pins affected by the disease become brown and do not further develop. |

|

|

What to do:

|

|

Die-back disease (Virus) It causes spots in the casing soil where no mycelial growth occurs. Around these spots, mushrooms of low quality appear with long stems and dirty caps. Sometimes the only indication of a virus infection is low yield. In severe cases, a few deformed mushrooms are produced. The disease can be introduced to the farm by infected spawn. It is spread by spores and mycelium from infected mushrooms. Mushrooms affected with the virus open fast, releasing infected spores. Sometimes, mushrooms that were formed inside the casing layer come out already open. Spores from infected mushrooms are easily carried by wind, insets, on implement, clothes and hands of personnel. |

|

|

What to do:

|

|

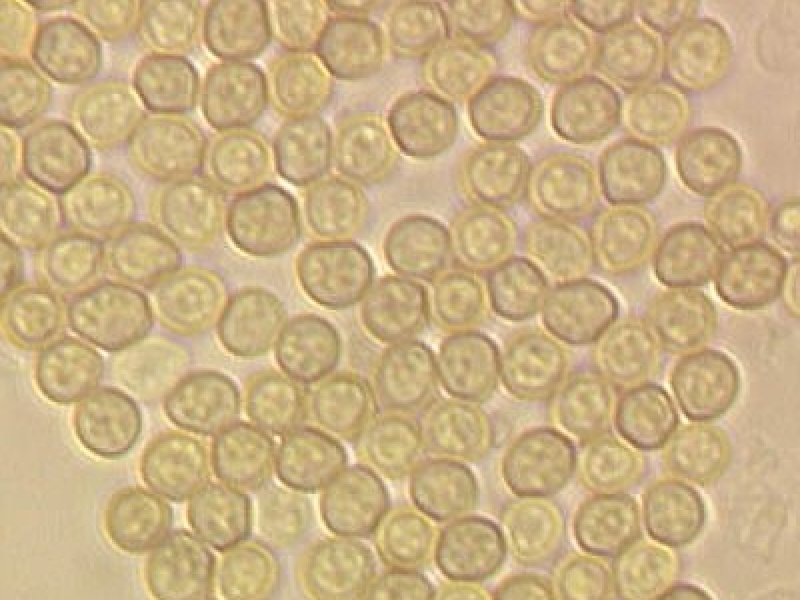

Green mould (Trichoderma aggressivum var. aggressivum) This fungus is soil-borne. There are many species of the fungus but Trichoderma aggressivum var. aggressivum (Trichoderma harzianum biotype 4 (Th4)) is a major problem particularly to button mushrooms. It gains entry to growing rooms primarily through contaminated personnel and equipment. Other sources include poorly composted substrate or carryover in rooms that were not sufficiently steamed off. Once introduced, it rapidly spreads into large disease areas from infection source. Infection of casing soil can result in serious losses. Green mold is characterized by dense white mycelial growth followed by extensive green patches on casing/compost or mushroom caps. The spores of the fungus are sticky and can easily be spread by flies, mites and workers to previously uninfected area. Red pepper mites are often associated with the disease. |

|

|

What to do:

|

|

Mites Mites belong to the spider family. They are eight-legged compared to insects which are six-legged. They are very small and are usually not noticed until large numbers are present. Many different kinds of mites are encountered during mushroom cultivation process. Some mites feed on fungi and bacteria that exist in great amounts in decaying organic materials used as a substrate in mushroom production. Other members of mites are predators that mainly feed on nematodes and smaller mites. Only a few of them are considered as mushroom pests. These include mushroom mites or tarsonemid mites (Tarsonemus myceliophagus) and red pepper mites (Pygmephorus sellnicki). The mushroom mites are so small, that they are not seen with a naked eye. They are shiny, light brown in colour feeding on the mushroom mycelium and mycelium of many other competing fungi present in the substrate. They gnaw the bases of mushroom stipes (stalks of mushroom) which in result become rounded and obtain a reddish-brown shade. The amount of damage they bring to the growing crop will depend on the time and degree of infestation. If a large population of mites enters the batch at spawning, the damage can be significant. Red pepper mites got their names from their reddish-brown colour and are often found moving on the mushroom caps or the casing surface. These mites are not regarded as primary pests, their presence is usually an indicator that Trichoderma (green mould) is present in the compost. These mites feed on various weed moulds but not mushrooms, thus their presence indicates that the compost is unsatisfactory. They are yellowish-brown in colour, 0.25 mm in length and have a flattened appearance. They spread spores of Trichoderma from bag to bag. They feed on competing fungi and that is why their presence indicates poorly prepared compost and possible presence of Trichoderma. They reproduce very fast one female can lay up to 160 eggs within 5 days. They cause browning of mushroom heads and promote the spreading of green molds not only in the infected room, but also in the whole farm. When their population is high, they cause discomfort and even allergy to mushroom pickers at work. |

|

|

What to do:

|

|

Mushroom flies Sciarid flies (Lycoriella spp.) and phorid flies (Megaselia spp.) can be a major problem in mushroom production. Adult flies enter mushroom houses through openings and cracks. They are attracted by the smell of substrate (compost) and growing mushrooms. They lay eggs in the substrate, casing layer and mushrooms. Each female can lay up to 170 eggs. At a temperature of 24.5°C development from egg to adult takes about 21 days. Emerging larvae (maggots) feed on the substrate, mushroom mycelium and developing mushrooms. Damaged mycelium results in the formation of pins brown in colour and having a leathery surface. Developing pins and young mushrooms may not survive after larval attack. Infested young mushrooms become hollow and shrink, and may eventually die. Larvae may also tunnel ripe mushrooms forming many passage ways and holes, which makes the mushrooms unsuitable for human consumption. The affected substrate areas turn into swampy masses with a foul odour in which mushroom mycelium will not be able to grow. Adult flies are known to spread mushroom diseases and mites. They are also a nuisance to workers. |

|

|

What to do:

|

|

Mycophytic nematodes (Aphelenchoides composticola and Ditylenchus myceliophagus) These nematodes (eelworms) are common inhabitants of most agricultural soils. They feed on mushroom mycelium. They gain access to growing rooms in substrate and casing soil. They are spread by insects, personnel and implements. Affected areas become unpleasantly wet and soft with a foul odour because of anaerobic (not needing oxygen to live) bacteria activities. Nematodes affect yield and quality. The degree of crop losses depends on the time and level of the initial infection. Infection at spawning time can have an effect on mycelial growth and thus making cultivation unprofitable. Infection occurring later causes only minor crop losses and goes unnoticed by the mushroom grower. The presence of nematodes on mushroom beds indicates bad cultivation conditions, that is, poor substrate and casing soil preparation and non-observance of sanitation and hygiene. |

|

|

What to do:

|

|

Wet bubble (Mycogone perniciosa) This disease like dry bubble is soil-borne. Infested soil may be primary source of infection. Infection usually occurs at casing. The disease is spread within a house mainly by water splash, on clothing, equipment, flies or mites. Cross-contamination between houses can also take place. Young pin heads infected by Mycogone grow into shapeless lumps cauliflower-like which have a velvety appearance initially and eventually break down producing small amber droplets of liquid on the surface. It can also appear as gray fuzzy growth on gills (a series of radially arranged (from the center) flat surfaces located on the underside of the cap on which spores are formed). |

|

|

What to do:

|

Geographical Distribution in Africa

Geographical Distribution of Mushroom in Africa. Updated on 8 July 2019. Source FAOSTAT

© OpenStreetMap contributors, © OpenMapTiles, GBIF. https://www.gbif.org/species/5243447

General Information and Agronomic Aspects

Introduction

Mushrooms are classified under various families and genera. One prominent family is the Agaricaceae family, and a well-known genus within this family is Agaricus. The genus Agaricus includes the common button mushroom (Agaricus bisporus), widely consumed across the globe. Beyond Agaricus, there are genera like Pleurotus (oyster mushrooms), Lentinula (shiitake mushrooms), and Hypsizygus (elm oyster mushrooms), among others, each offering unique flavors and textures.

© Maundu P, 2001

© Maundu P, 2006

© Maundu P, 2001

Species account

|

| Oyster mushrooms |

|

© Courtesy of AIRC, Nairobi, Kenya |

|

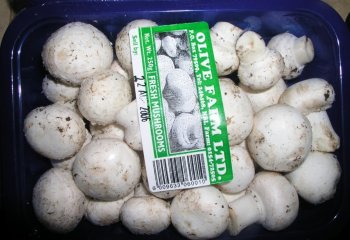

| Button mushrooms |

|

© Courtesy of Wikipedia

|

Agronomic aspects

1) potential markets and supply chains

2) source(s) of high quality spawn ('seeds' of mushrooms)

3) availability of substrate (material on which mushrooms grow)

4) availability of supplements (additional nutrients to the substrate)

5) production plan to ensure continuous production

Nutritional value

Table : Nutritional value of 100 g edible portion

Code Food Name |

Mushroom, fresh, raw |

Mushroom, fresh, boiled, drained (without salt) |

Mushroom, fresh, stewed (without salt) |

Mushroom, dried, raw |

Mushroom, dried, boiled, drained (without salt) |

Mushroom, raw, canned in brine (drained) |

Recommended daily allowance (approx.) for adults a |

Edible conversion factor |

1 |

1 |

1 |

1 |

1 |

1 |

|

Energy (kJ) |

148 |

203 |

183 |

1180 |

674 |

73 |

9623 |

Energy (kcal) |

35 |

48 |

43 |

283 |

162 |

18 |

2300 |

Water (g) |

89.7 |

85.9 |

87.3 |

11.9 |

49.6 |

93 |

2000-3000c |

Protein (g) |

2.3 |

3.2 |

2.8 |

12.3 |

7 |

1.5 |

50 |

Fat (g) |

0.4 |

0.5 |

0.5 |

[2.9] |

1.6 |

0.4 |

<30 (male), <20 (female)b |

Carbohydrate available (g) |

4.5 |

6.1 |

5.5 |

32.4 |

18.5 |

0.2 |

225 -325g |

Fibre (g) |

2.3 |

3.1 |

2.8 |

39.1 |

22.4 |

3.7 |

30d |

Ash (g) |

0.9 |

1.2 |

1.1 |

1.4 |

0.8 |

1.2 |

|

Minerals |

|||||||

Ca (mg) |

16 |

21 |

20 |

24 |

14 |

4 |

800 |

Fe (mg) |

0.3 |

0.3 |

0.4 |

5.5 |

2.3 |

1 |

14 |

Mg (mg) |

15 |

12 |

19 |

136 |

47 |

4 |

300 |

P (mg) |

105 |

129 |

130 |

702 |

361 |

54 |

800 |

K (mg) |

318 |

218 |

393 |

326 |

93 |

24 |

4,700f |

Na (mg) |

8 |

8 |

10 |

5 |

3 |

300 |

<2300e |

Zn (mg) |

0.17 |

0.17 |

0.21 |

8.7 |

3.72 |

0 |

15 |

Se (mcg) |

16 |

20 |

20 |

0 |

0 |

16 |

30 |

Bioctive compounds. |

|||||||

Vit A RAE (mcg) |

0 |

0 |

0 |

0 |

0 |

4 |

800 |

Vit A RE (mcg) |

0 |

0 |

0 |

0 |

0 |

7 |

800 |

Retinol (mcg) |

0 |

0 |

0 |

0 |

0 |

0 |

1000 |

b-carotene |

0 |

0 |

0 |

0 |

0 |

42 |

600 – 1500g |

Thiamin (mg) |

0.1 |

0.09 |

0.11 |

0.09 |

0.24 |

0.23 |

1.4 |

Riboflavin (mg) |

0.4 |

0.36 |

0.47 |

0.06 |

0.17 |

0.05 |

1.6 |

Niacin (mg) |

0.7 |

0.6 |

0.8 |

1.4 |

3.77 |

1.3 |

18 |

Dietary Folate Eq. (mcg) |

23 |

16 |

20 |

47 |

163 |

22 |

400f |

Food folate (mcg) |

23 |

16 |

20 |

47 |

163 |

22 |

400f |

Vit B12 (mg) |

0 |

0 |

0 |

0 |

0 |

0 |

3 |

Vit C (mg) |

0 |

0 |

0 |

0 |

0 |

3 |

60 |

Source (Nutrient data): FAO/Government of Kenya. 2018. Kenya Food Composition Tables. Nairobi, 254 pp. http://www.fao.org/3/I9120EN/i9120en.pdf

a Lewis, J. 2019. Codex nutrient reference values. Rome. FAO and WHO

b NHS (refers to saturated fat)

c https://www.hsph.harvard.edu/nutritionsource/water/

d British Heart Foundation

e FDA

f NIH

g Mayo Clinic

h-West African food composition table

Nutritive Value per 100 g of edible Portion

| Raw or Cooked Vegetable | Food Energy (Calories / %Daily Value*) |

Carbohydrates (g / %DV) |

Fat (g / %DV) |

Protein (g / %DV) |

Calcium (g / %DV) |

Phosphorus (mg / %DV) |

Iron (mg / %DV) |

Potassium (mg / %DV) |

Vitamin A (I.U) |

Vitamin C (I.U) |

Vitamin B 6 (I.U) |

Vitamin B 12 (I.U) |

Thiamine (mg / %DV) |

Riboflavin (mg / %DV) |

Ash (g / %DV) |

| Mushroom, oyster raw | 43.0 / 2% | 6.5 / 2% | 0.4 / 1% | 3.3 / 7% | 3.0 / 0% | 120 / 12% | 1.3 / 7% | 420 / 12% | 48 IU / 1% | 0.0 / 0% | 0.1 / 6% | 0.0 / 0% | 0.1 / 8% | 0.3 / 28% | 1.0 |

*Percent Daily Values are based on a 2000 calorie diet. Your daily values may be higher or lower, depending on your calorie needs.

Markets and marketing

When considering producing mushrooms as a business, check on the following:

2) their price and availability

3) current distributors and possibility of business relationship

4) possibility of value addition

© Maundu P, 2001

© Maundu P, 2006

© Maundu P, 2001

Production plan

|

| Spawn in a bottle |

|

© Courtesy of AIRC, Nairobi, Kenya |

Spawn

It is a planting material equivalent of farmers' seed for starting mushroom cultures. It is made from mycelia (plural of mycelium) of mushroom grown on a carrier such as grains and is produced in specialized laboratories under sterile conditions. The amount of spawn needed is equal to 4-6% of the wet weight of the substrate. For example if the wet weight of the substrate is 50 kg, 2-3 kg of spawn is required. One kg of spawn may cost between Kenya shillings 600 and 800.

In Kenya, there are a number of institutions such as JKUAT producing high quality spawn. Farmers who need spawn or training can contact the university at the following address: Business Manager, JKUAT Enterprises Ltd., P.O. Box 62000-00200, Nairobi. Mobile phone: 0722 728812.

|

| Wheat straw |

|

© Courtesy of AIRC, Nairobi, Kenya |

Substrate

Supplements

Mushroom house

|

| A grass thatched mud mushroom house |

|

© Courtesy of AIRC, Nairobi, Kenya |

|

| Wooden shelves holding bags in the house |

|

© Courtesy of AIRC, Nairobi, Kenya |

Overview on production of mushrooms

Phases of cultivation of button and oyster mushrooms

| Phase | Time span and temperature | Remarks |

| Substrate preparation | 6-8 hours for soaking shredded straw in water for oyster. Pre-wetting of wheat straw for button is done for 3 days | Selection of substrate. Cereal straws are preferred. Wheat straw is ideal for button. In case of oyster it involves shredding, soaking in water to 70% moisture content (1), draining excess water, adding supplements plus lime and packing into polybags. |

| Composting | 18-20 days | Oyster does not require composted substrate. Only applicable to button. Involves pre-wetting of wheat straw to 70% moisture content, adding supplements plus lime and gypsum. Good compost is dark brown, 70% moisture content and pH 8.0 - 8.5 (2) |

| Pasteurization and conditioning | 4-6 hours of steam heating at 60°C for oyster and cool polybags to 20-25°C. For button steam for 8 hours and lower the heat for 4-5 days at 45-50°C then cool to 22-25°C | Steam heating of oyster polybags is done in water drums but it can also be done in hot water at boiling point for 1 hour. Button steaming is done in special chambers (tunnels). Conditioning is to remove ammonia gas which is poisonous for button. Cooling is in preparation for spawning. The moisture content of the substrate then should be 67-70% |

| Spawning and incubation | 5-10 days incubation for oyster; 15 days for button at 23-25°C | Applying spawn to substrate in polybags. The growing room should be kept humid (RH 65-95%) (3) with dim lighting just sufficient to read a newspaper |

| Casing | Sterilize casing soil for 4 hours at 60°C. Casing run (4) is 14-15 days at 25°C | This is not applicable in oyster production. Casing is applying a thin layer of red top soil added with murram and lime on top of fully colonized substrate. Casing soil should be kept wet but not waterlogged. Substrate turns white to grayish due to the colour of mycelium. It is now ready for fruiting. |

| Pinning | Oyster 5-10 days in the growing house at 23-25°C. Button 7-10 days but the growing house temperature will depend on variety (5) | Pinning is when mycelia start fruiting (formation of very young mushroom known as 'pin heads'). It takes 3-4 days for pin heads to develop into mature mushrooms. RH required is 85-95%. |

| Harvesting | Oyster about 30 days, button 30-40 days from spawning to harvesting | Oyster harvesting is done when the mushroom ear is 7.5-10 cm in diameter, turgid and bright in colour. Button is picked at the young stage before opening. Repeated over 7-10 day cycles |

(1) When the substrate is squeezed between the fingers it should give 2 to 3 drops of water. If it gives more drops, continue draining and with fewer drops add more water.

(2) pH is a measure of acidity. A pH value of 7 is neutral, lower than 7 is acidic and above 7 is alkaline. It can be determined using a pH meter. pH meters are readily available in shops selling laboratory equipment for schools in urban areas of Kenya.

(3) Relative humidity (RH) is the percentage of moisture in the air compared to the maximal amount that the air can hold at that temperature and pressure. It can be monitored by using a hydrometer which can be bought in shops selling laboratory equipment. If the RH is low, spray clean water on the floor or place pots with water in the room. If the RH is above the required, open windows or vents of the room.

(4) Casing run is the period in which the mycelia is left to grow on the casing soil.

(5) There are varieties grown: white mushroom or 'champignon') (Agaricus bisporus) and tropical mushroom (Agaricus bitorquis). During pinning the temperature in the growing house should be reduced from 25 to 20-22°C for tropical mushroom, and for white mushroom to 12-18°C.

Yield

Post-harvest management

© Maundu P, 2001

© Maundu P, 2006

© Maundu P, 2001

General Information on Pests and Diseases

Mushroom abnormalities

1. Formation of scales or "crocodile skin"

Causes:

- Very dry air

- Strong air movement with low relative humidity

- Shortcomings in the air supply and distribution system

- Tendency of the strain to form scales

- Damage done by pesticides

2. Formation of stroma (dense layer of mycelium without fruiting on casing soil)

Causes:

- Low-quality degenerating mushroom strain

- Mycelial growth in a poorly ventilated casing layer, with a high concentration of carbon dioxide, high temperature and low humidity, and a high volume of evaporation

- Overly long period of mycelial growth in the casing layer

- Petroleum-based fumes or chemicals

3. Rosecomb (misshapen cap with gills on the cap)

Causes:

- Casing layer contaminated by mineral oils

- Contamination by petroleum-based materials

4. Outgrowths on mushroom caps - "cock's comb"

Causes:

- An overdose of pesticides

- Casing layer contaminated with chemicals

- Effect of exhaust gases, heating appliances, diesel oil, formalin vapors, dissolvers, paint

5. Thick stipes, small caps

Cause:

- Excessively high carbon dioxide level on the initial stage of growth

6. A small cap on a normal stipe

Causes:

- Improper climatic conditions for specific strains

- Susceptibility of some strains

| Bacterial blotch (Pseudomonas tolaasi) The main source of bacterial blotch in the mushroom farm is the casing soil. The disease is favoured by dampness [high humidity (over RH 85%), high temperatures (over 20°C ) and poor ventilation in the growing houses]. It can be spread by the workers' hands, irrigation water and on the inventory. Mushroom flies and mites also spread the disease. The first disease symptoms appear in areas of caps that have been moist for a longest time and areas where mushroom caps touch. Symptoms include spots that darken becoming chocolate-brown in colour and slimy. It can also cause distortion and splitting of the stipes. When the infection is severe, spots spread throughout the whole mushroom surface. Seriously diseased mushrooms can become deformed and the caps can decay giving a foul (unpleasant) odour. Young pins affected by the disease become brown and do not further develop. What to do:

|

| Green mould (Trichoderma aggressivum var. aggressivum) This fungus is soil-borne. There are many species of the fungus but Trichoderma aggressivum var. aggressivum (Trichoderma harzianum biotype 4 (Th4)) is a major problem particularly to button mushrooms. It gains entry to growing rooms primarily through contaminated personnel and equipment. Other sources include poorly composted substrate or carryover in rooms that were not sufficiently steamed off. Once introduced, it rapidly spreads into large disease areas from infection source. Infection of casing soil can result in serious losses. Green mold is characterized by dense white mycelial growth followed by extensive green patches on casing/compost or mushroom caps. The spores of the fungus are sticky and can easily be spread by flies, mites and workers to previously uninfected area. Red pepper mites are often associated with the disease. What to do:

|

| Mycophytic nematodes (Aphelenchoides composticola and Ditylenchus myceliophagus) These nematodes (eelworms) are common inhabitants of most agricultural soils. They feed on mushroom mycelium. They gain access to growing rooms in substrate and casing soil. They are spread by insects, personnel and implements. Affected areas become unpleasantly wet and soft with a foul odour because of anaerobic (not needing oxygen to live) bacteria activities. Nematodes affect yield and quality. The degree of crop losses depends on the time and level of the initial infection. Infection at spawning time can have an effect on mycelial growth and thus making cultivation unprofitable. Infection occurring later causes only minor crop losses and goes unnoticed by the mushroom grower. The presence of nematodes on mushroom beds indicates bad cultivation conditions, that is, poor substrate and casing soil preparation and non-observance of sanitation and hygiene. What to do:

|

| It causes spots in the casing soil where no mycelial growth occurs. Around these spots, mushrooms of low quality appear with long stems and dirty caps. Sometimes the only indication of a virus infection is low yield. In severe cases, a few deformed mushrooms are produced. The disease can be introduced to the farm by infected spawn. It is spread by spores and mycelium from infected mushrooms. Mushrooms affected with the virus open fast, releasing infected spores. Sometimes, mushrooms that were formed inside the casing layer come out already open. Spores from infected mushrooms are easily carried by wind, insets, on implement, clothes and hands of personnel. What to do:

|

| Wet bubble (Mycogone perniciosa) This disease like dry bubble is soil-borne. Infested soil may be primary source of infection. Infection usually occurs at casing. The disease is spread within a house mainly by water splash, on clothing, equipment, flies or mites. Cross-contamination between houses can also take place. Young pin heads infected by Mycogone grow into shapeless lumps cauliflower-like which have a velvety appearance initially and eventually break down producing small amber droplets of liquid on the surface. It can also appear as gray fuzzy growth on gills (a series of radially arranged (from the center) flat surfaces located on the underside of the cap on which spores are formed). What to do:

|

Information Source Links

- AIRC (2000). Local and Export Vegetables. Growing Manual. Ministry of Agriculture and Rural Development, Kenya / Japan International Cooperation Agency. Reprinted by the Agricultural Information Centre, Nairobi, Kenya. Email: agriinfocentre@yahoo.com; agrinfodata@yahoo.com

- AIRC (2009). Guide to Growing Mushrooms. Published by the Agricultural Information Centre, Nairobi, Kenya. Email: agriinfocentre@yahoo.com; agrinfodata@yahoo.com

- Fungiculture: www.wikipedia.org

- Nutrition Data www.nutritiondata.com.

- Peter Oei (2003). Mushroom Cultivation. 3rd. Edition. Appropriate Technology for Mushroom Growers. Backhuys Publishers, Leiden, The Netherlands. ISBN: 90-5782-137-0

- Tsarev, A.V. (2003). Mushroom Growing Technology

Contact Information

- Jomo Kenyatta University of Agriculture and Technology Enterprises Limited (JKUATES). Telephone 0724 256696/ +254 67 52420/ 0721 167244 . Email address: jkuates@jkuates.jkuat.ac.ke

Review Process

Dr. Patrick Maundu, James Kioko, Charei Munene and Monique Hunziker, July 2024